2026 Best Shipping Container Fabrication Techniques and Trends?

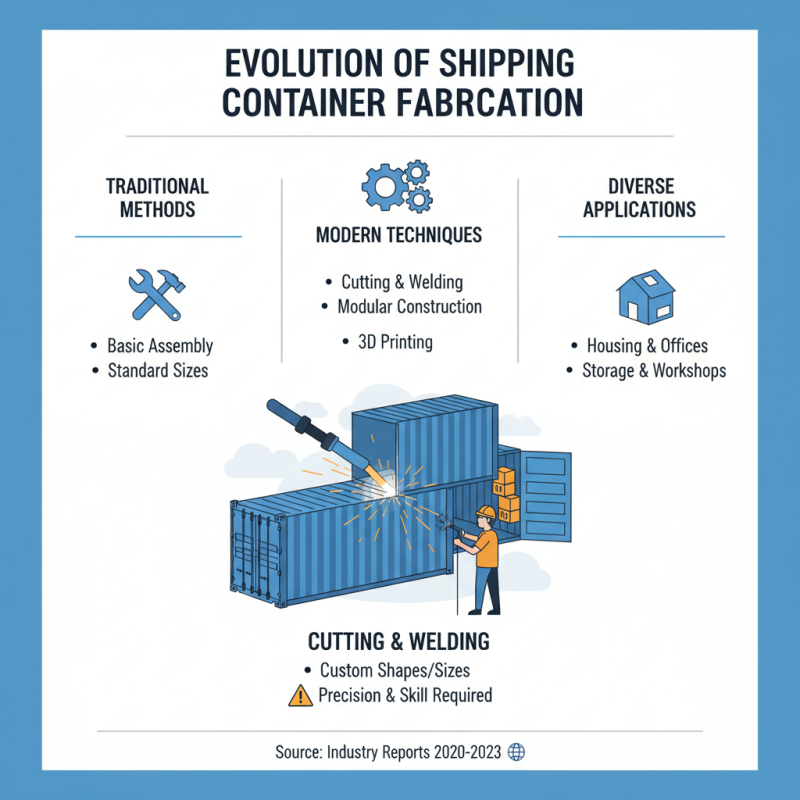

The world of shipping container fabrication is evolving rapidly. As we approach 2026, innovative techniques are reshaping how we repurpose these containers. This shift is driven by sustainability and creative design. Many now see shipping containers as not just transport units, but versatile building blocks.

Different trends are emerging in fabrication. One trend is the use of eco-friendly materials alongside containers. This enhances their sustainability. Moreover, modular designs are gaining traction. Such designs allow for easy expansion and customization. New technologies are reducing costs but also posing challenges. The learning curve can be steep for many in the industry.

As professionals dive into this world, they often grapple with balancing creativity and practicality. Some may overlook safety standards for aesthetics. This raises questions about responsibility in design. The excitement around shipping container fabrication must be matched with careful consideration. With innovative trends on the horizon, the future is bright but complex.

Overview of Shipping Container Fabrication Techniques

Shipping container fabrication has evolved significantly in recent years. A variety of techniques have emerged. These techniques accommodate various needs, from housing to storage solutions. One popular method is cutting and welding, which allows for customized shapes and sizes. This technique requires precision and skilled labor. Improper cuts can waste materials and lead to structural weaknesses.

Another trend in fabrication is modular assembly. This method involves pre-fabricating components off-site. The components are then transported for quick assembly at the final location. While this technique speeds up the construction process, challenges remain. Ensuring that all parts fit correctly can be problematic. Builders must communicate effectively to evade costly mistakes.

Eco-friendly practices are also gaining traction in shipping container fabrication. Reusing containers reduces waste. Innovations such as insulation and weatherproofing enhance energy efficiency. However, finding sustainable materials can be challenging. Not all materials meet environmental standards. This inconsistency raises questions about long-term sustainability in the industry.

Current Trends in Shipping Container Design and Construction

The design and construction of shipping containers have come a long way. Trends show a rise in

multifunctional spaces. Many people now use containers for homes, offices, and even cafes. This versatility sets a new standard in architecture. Customization is in high demand. Clients want unique designs that reflect their

personal style.

Sustainable building techniques are gaining traction. Recycling materials and solar panels are popular choices. However, issues like insulation and condensation remain concerns. It's crucial to address these problems during the construction phase. Architects and builders often overlook practical details. This can lead to inefficiencies later on.

Another emerging trend is the incorporation of

smart technology. Features like smart locks and energy-efficient systems are becoming common. These innovations enhance convenience but also carry risks. Security vulnerabilities are a significant concern. Finding a balance between technology and safety is essential. As the industry evolves, so must our approach to these challenges.

Sustainable Practices in Shipping Container Fabrication

Sustainable practices in shipping container fabrication are gaining traction. According to a recent report, about 25% of recycled materials are used in current fabrication processes. This trend not only reduces waste but also lowers the carbon footprint. Innovative methods, such as using reclaimed steel and repurposed wood, are becoming common.

Designers focus on eco-friendly insulation methods. Traditional insulation often relies on harmful materials. New techniques utilize recycled denim and natural fiber, enhancing energy efficiency. These changes may improve comfort and reduce energy costs in finished structures.

Challenges exist in this evolving landscape. Many manufacturers struggle to source sustainable materials. The supply chain remains inconsistent. Plus, public awareness of eco-friendly practices is still low. Greater education is necessary. The industry must reevaluate and adapt these practices for broader adoption.

Innovative Technologies for Enhancing Container Durability

In the realm of shipping container fabrication, innovative technologies are transforming how we enhance container durability. One prominent method involves the use of high-performance coatings. These specialized coatings not only resist corrosion but also withstand extreme weather conditions. They offer an additional layer of protection against physical damage, ensuring longevity.

Another approach gaining traction is modular reinforcement. By integrating lightweight composites, the structural integrity of containers is significantly improved. These materials provide flexibility and strength without adding excessive weight. However, integrating such technology can be expensive and complex. Manufacturers often face challenges in balancing cost and performance.

Emerging trends also include advanced welding techniques. These processes promise stronger joints and reduce the risk of fatigue. Yet, the necessary skills and equipment can be a barrier for some fabricators. As we explore these trends, it's essential to recognize that not all innovations will be immediately beneficial. Continuous evaluation and adaptation will be necessary to ensure lasting results.

Case Studies of Successful Container Fabrication Projects

Shipping container fabrication offers innovative solutions for construction. Successful projects often showcase creative uses. One notable case involved transforming shipping containers into a cozy coffee shop. The design prioritizes functionality and aesthetic appeal. With smart layout designs, the space feels inviting.

Tips: Focus on maximizing natural light. Use large windows to enhance ambiance. Consider the local environment when selecting materials.

Another case featured a vibrant community center. It provided various services to the neighborhood, turning unused land into a bustling hub. The project faced challenges in zoning laws but managed to navigate them successfully. Collaboration with local authorities proved essential.

Tips: Engage with the community early. Their input can lead to a more accepted design. Stay flexible to adapt to feedback during the process.

Each project serves as inspiration. The potential of shipping container fabrication expands beyond traditional structures. Experimentation is key in discovering new, fulfilling uses. Embrace imperfections; they often lead to unique solutions.

2026 Best Shipping Container Fabrication Techniques

Related Posts

-

Unlocking the Potential: Innovative Uses for Specialty Shipping Containers in Modern Industries

-

Exploring the Future of Sustainable Living with Innovative Shipping Container Fabrication

-

Transforming Spaces: The Versatile Benefits of Custom Built Shipping Containers in Modern Architecture

-

Unlocking the Potential of Custom Built Shipping Containers for Sustainable Living Solutions

-

Exploring the Versatility of Custom Cargo Containers: Innovative Uses for Modern Transport Needs

-

Top 10 Custom Shipping Container Builders for Your Next Project